Process mapping software

Lucidchart is an intelligent diagramming application that makes creating a process map easy with drag-and-drop shapes, ready-to-use templates, and more.

By registering, you agree to our Terms of Service and you acknowledge that you have read and understand our Privacy Policy.

Communicate complex processes with ease

Document and improve any plan or process

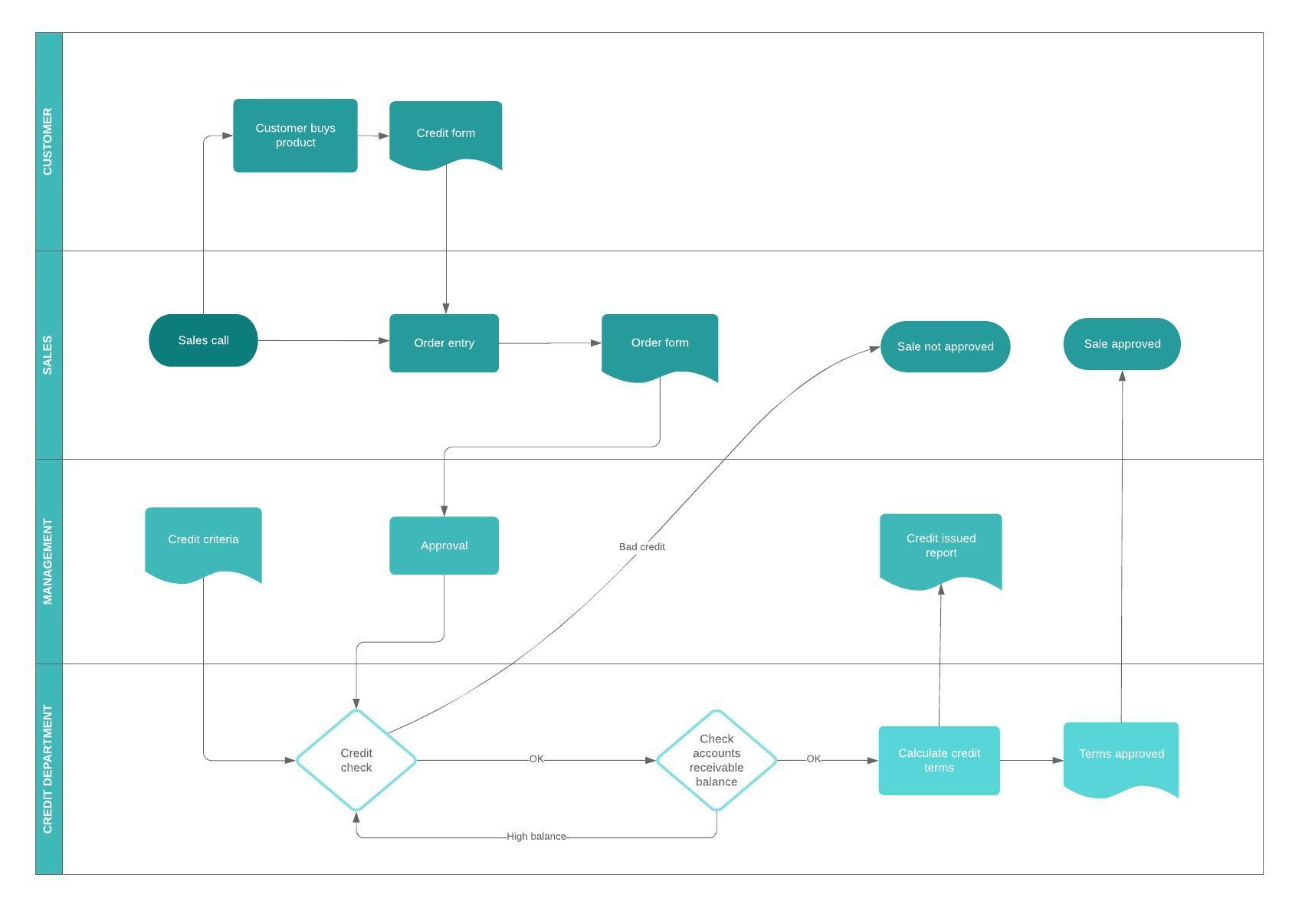

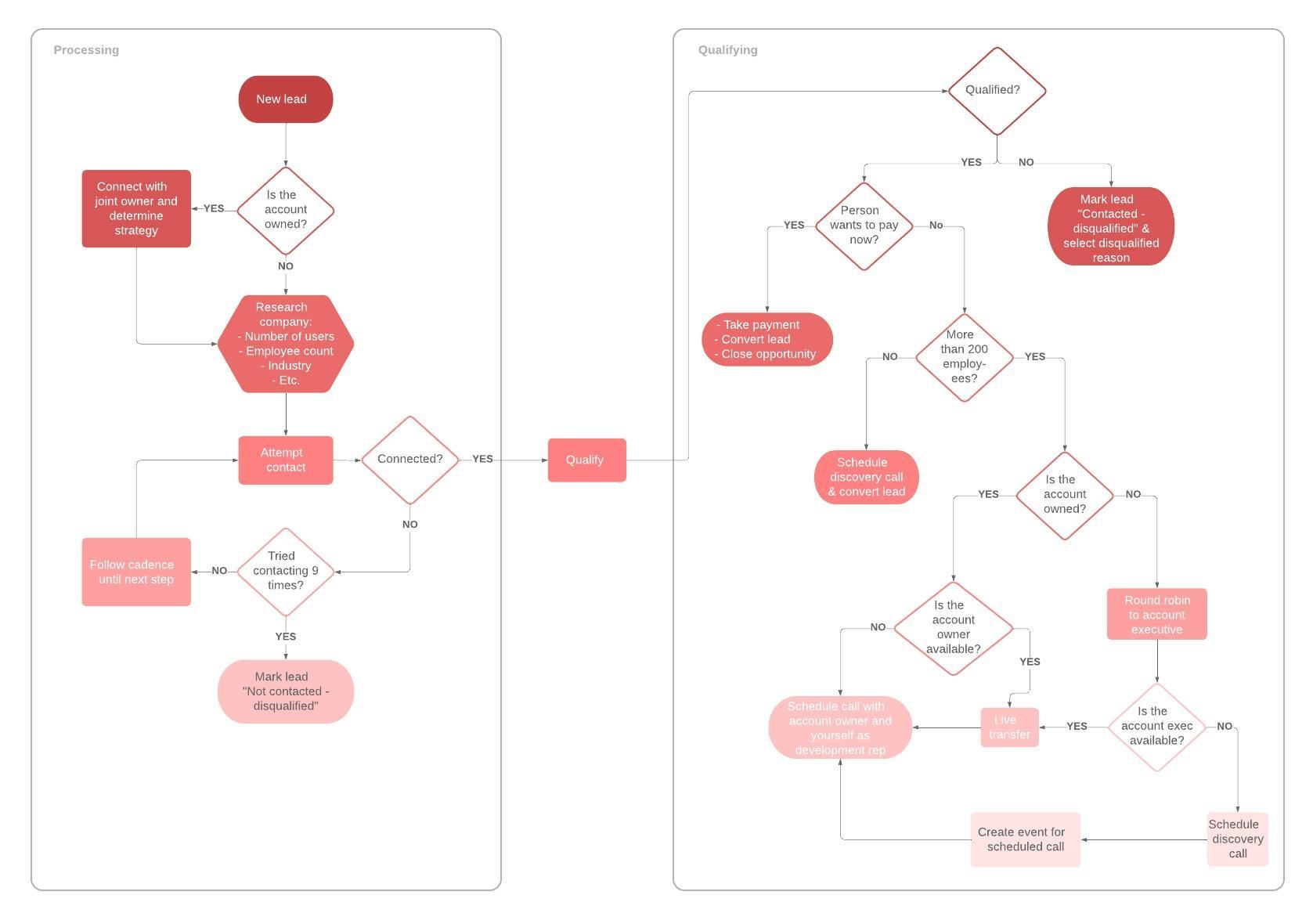

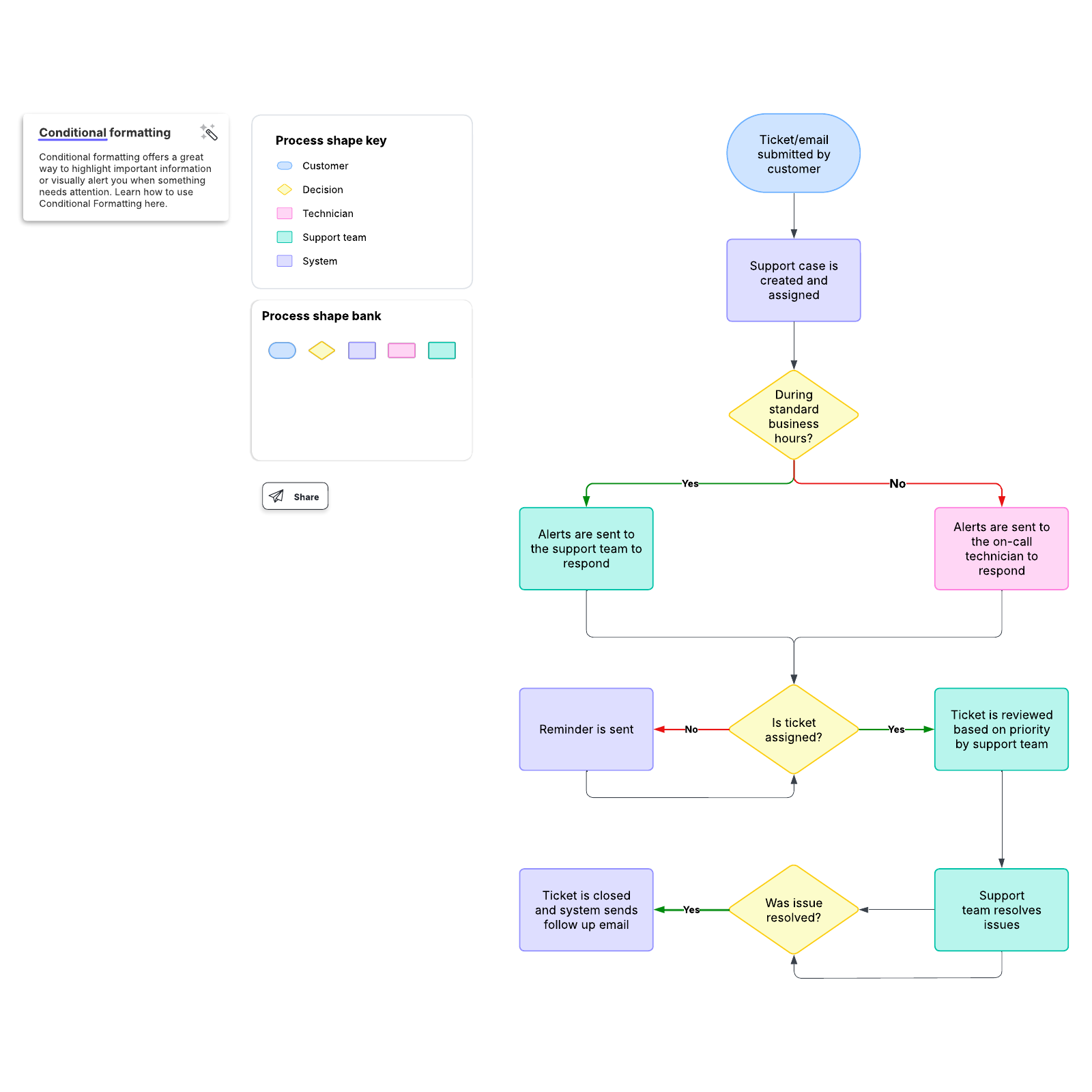

Create a clear, easy-to-read visualization of your process using our process mapping software. With extensive shape libraries, customizable templates, and intuitive formatting tools, Lucidchart helps you create detailed process maps online that meet your team’s specific needs.

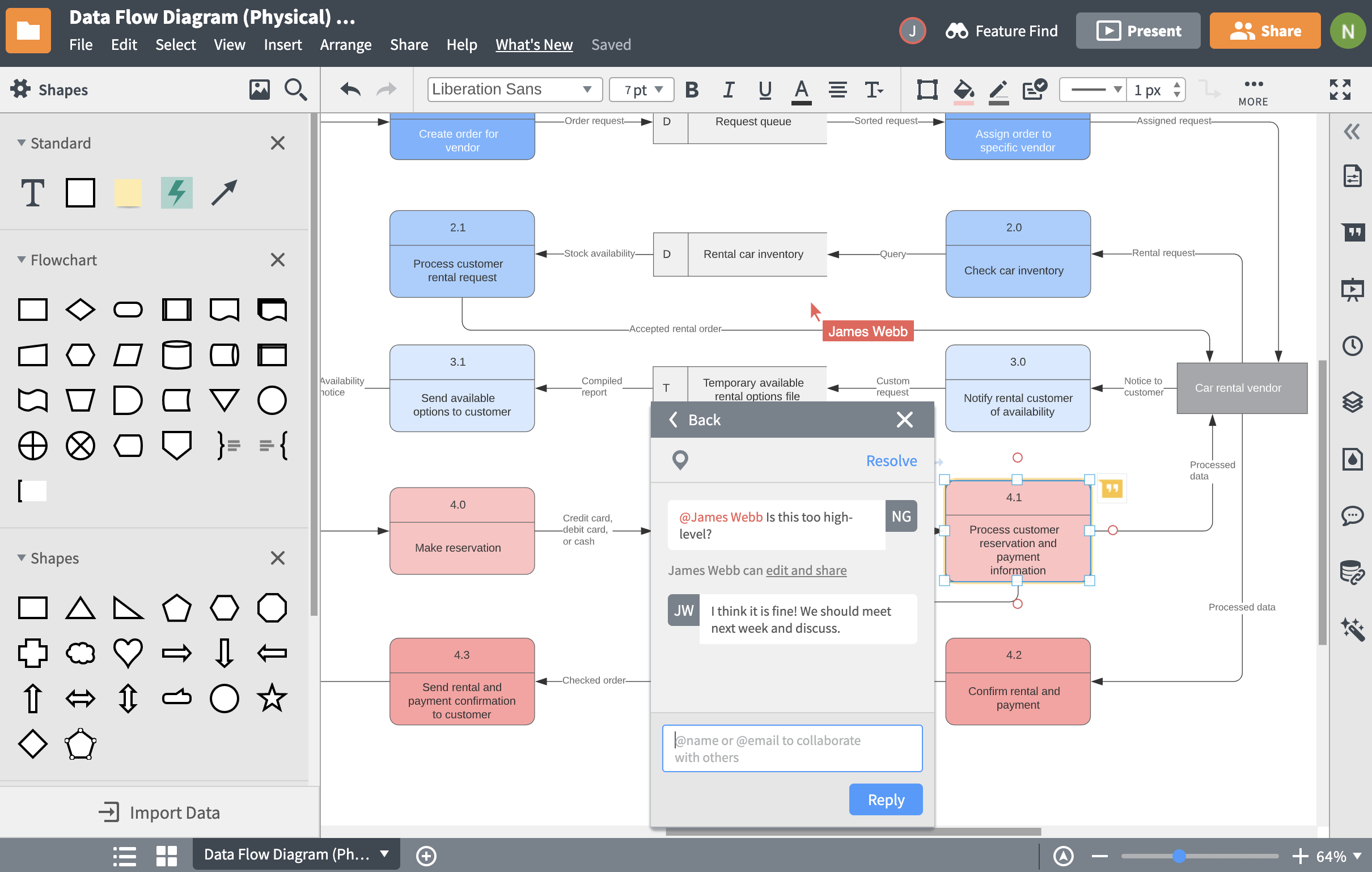

Collaborate in real time, no matter where your team is

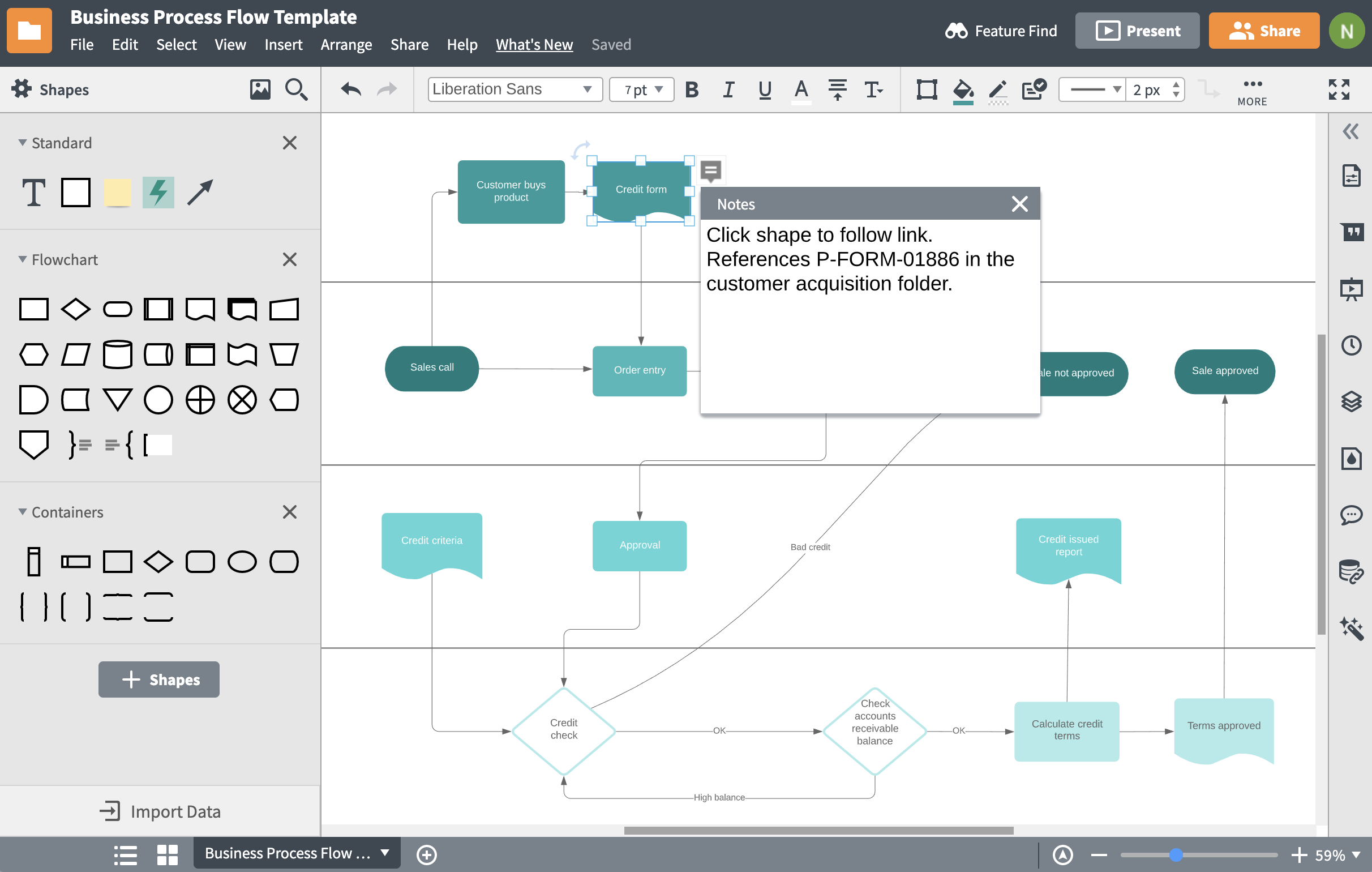

Lucidchart lets you collaborate with your stakeholders and team members in real time. Work simultaneously with your team in the same document, with all of your edits updating instantly, so you never miss input from your team. On Mac or PC, Lucidchart lets you create, edit, and share your diagram from anywhere, anytime.

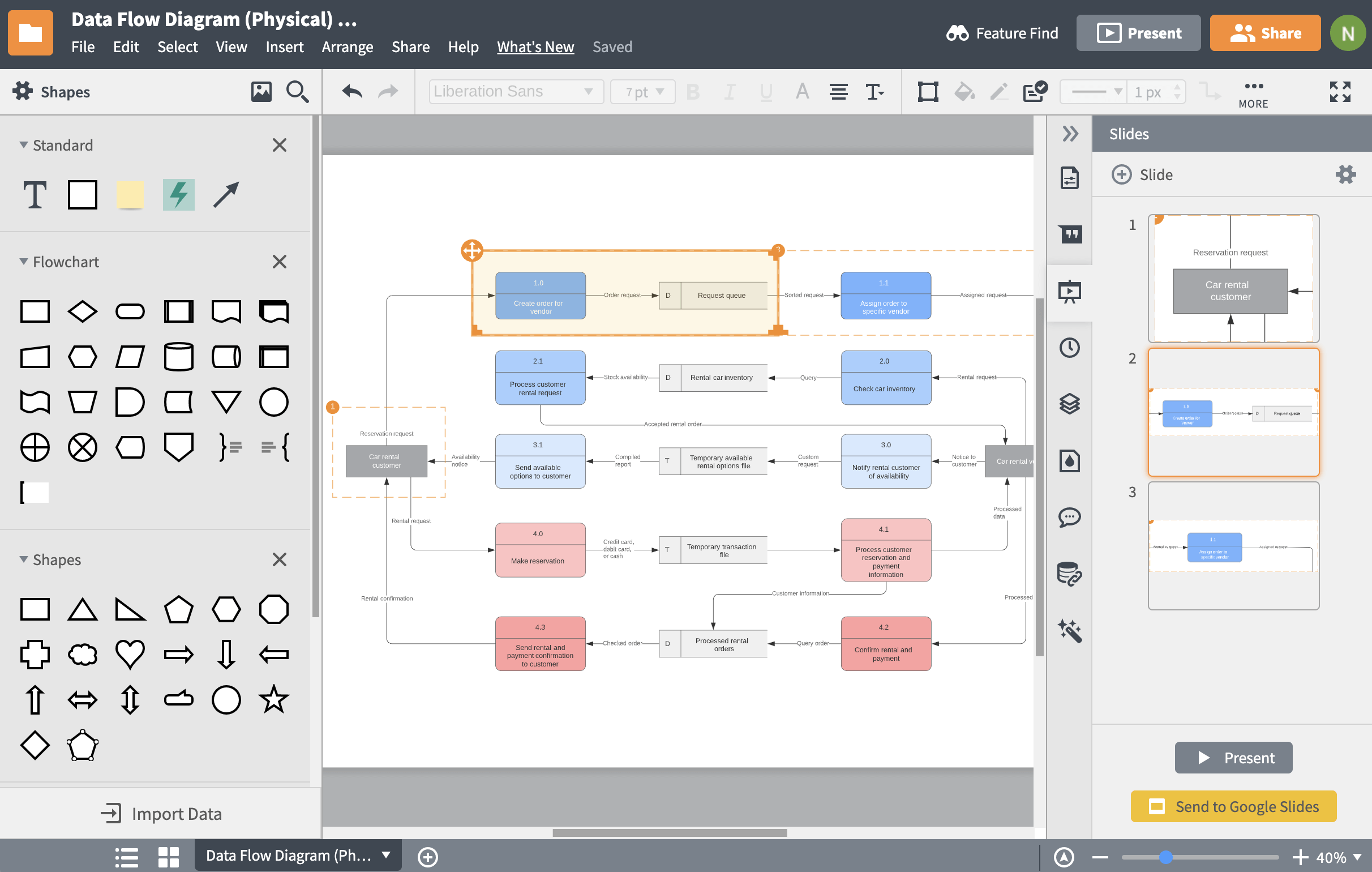

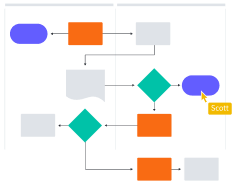

Keep your team on the same page with presentation mode

Whether you’re looking to present a high-level overview of your process to executives or want to take a closer look at specific tasks, our presentation mode has you covered. Easily switch from your canvas to our presentation mode to create clean, professional, and even interactive presentations in seconds.

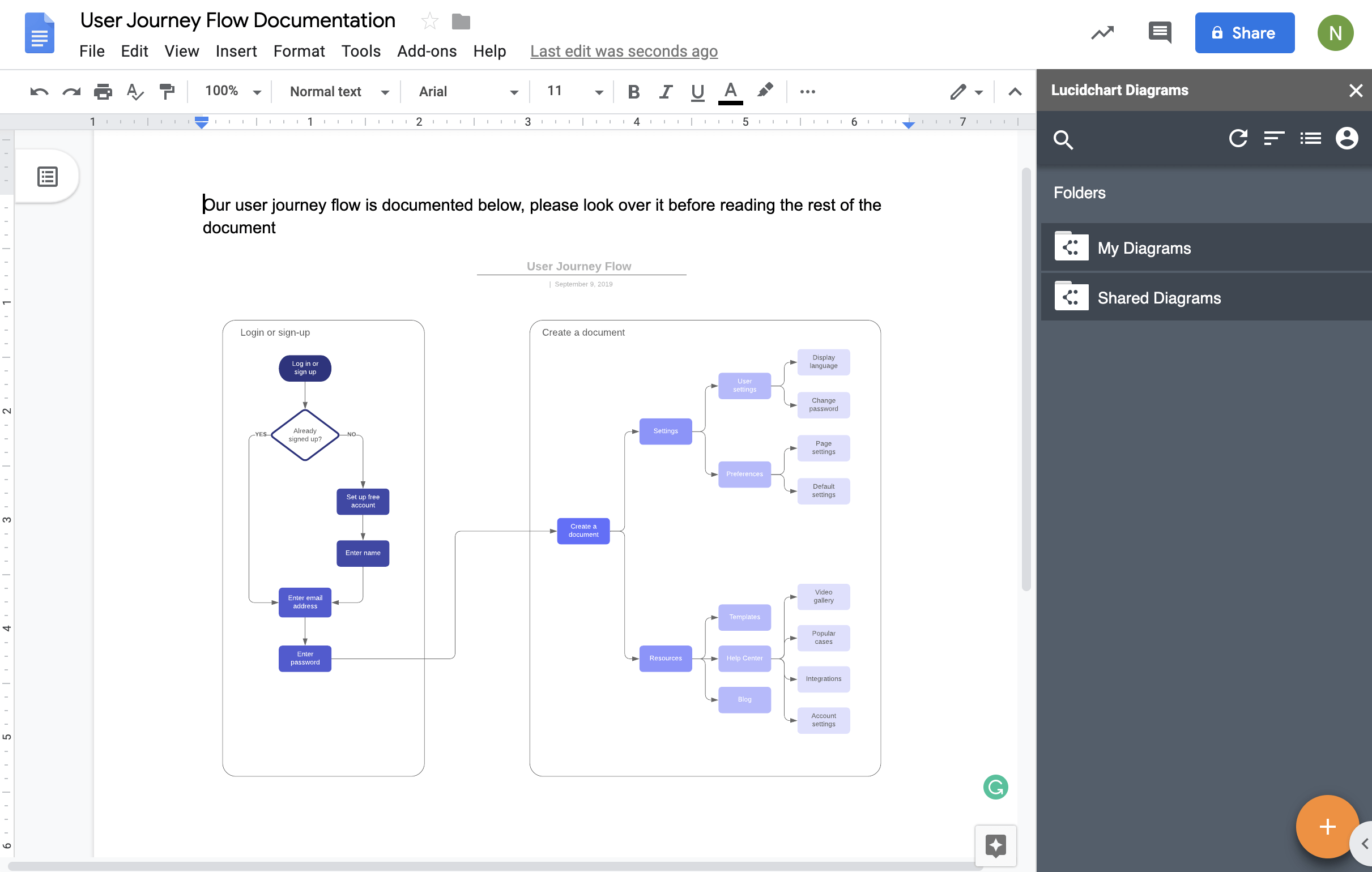

Leverage your Google account to make diagramming easier

Get even more out of your Google log-in with our online process map creator’s powerful integrations for G Suite. Our free add-ons for Google Docs, Sheets, and Slides allow you to insert your diagrams into text-heavy documents, spreadsheets, and slideshows with a few easy clicks.

Master the basics of Lucidchart in 3 minutes

master the basics of Lucidchart in 5 minutes

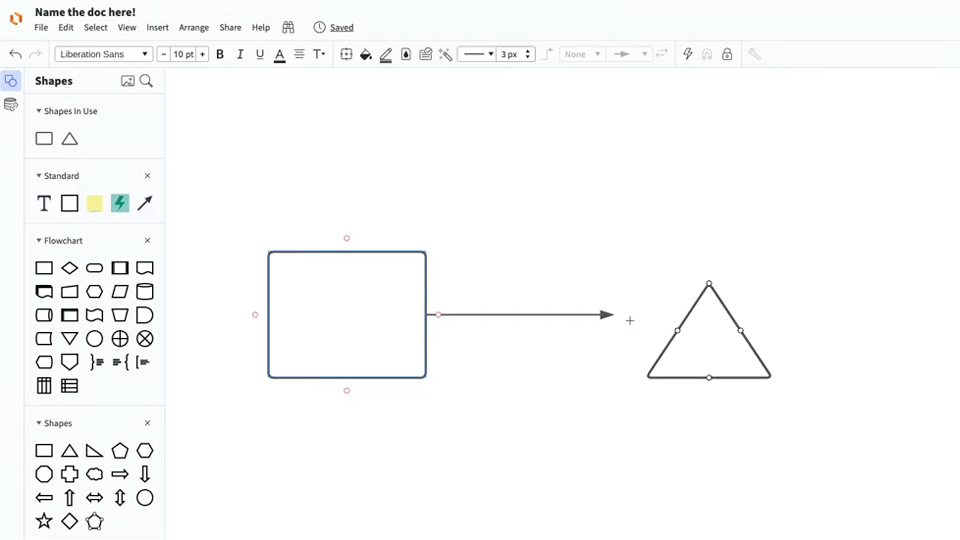

- Create your first process map from a template or blank canvas or import a document.

- Add text, shapes, and lines to customize your diagram.

- Learn how to adjust styling and formatting.

- Locate what you need with Feature Find.

- Share your diagram with your team to start collaborating.

Free Process map templates

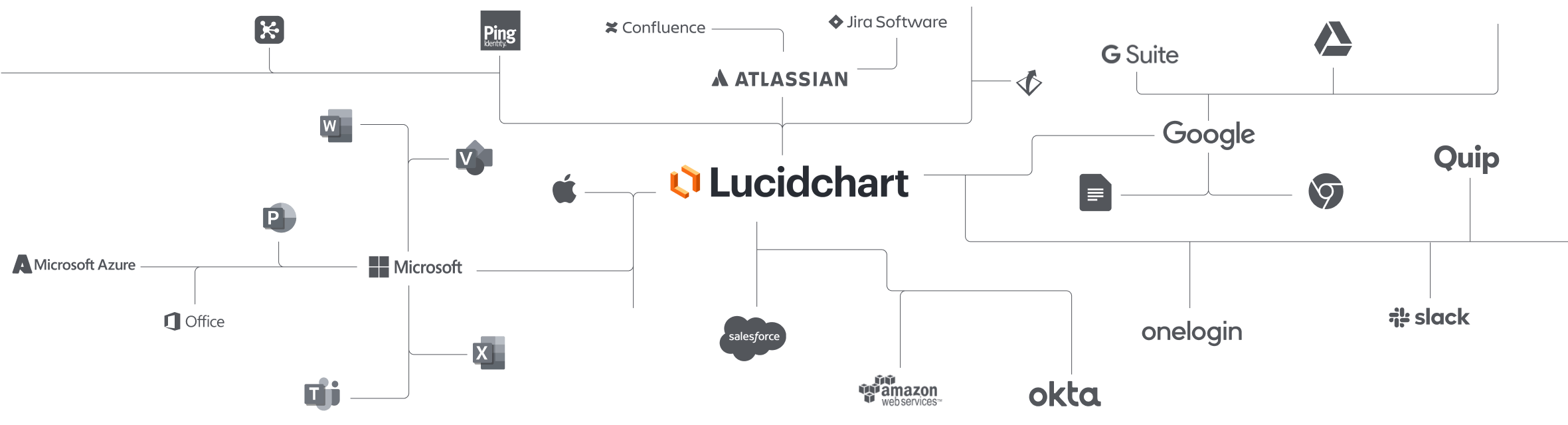

Lucidchart integrations

Connect Lucidchart to your favorite industry-leading apps.

See why teams choose Lucidchart

Diagram, visualize data, and collaborate all in one platform.

Collaboration

Create online process maps on any device with ease. Lucidchart helps teams collaborate in real time from anywhere in the world. Enhance productivity while working together with your team to achieve your product goals.

Clarity

Lucidchart brings clarity to the complex. Intelligent diagramming allows you to quickly visualize projects and processes from start to finish.

Alignment

Drive alignment with your team by collaborating in the same space. Quickly map out processes and ideas together in real time so that you never miss a beat.

Better Together

The Lucid Visual Collaboration Suite transforms the way you work from ideation to project completion. Brainstorm and plan in Lucidspark then map it out in Lucidchart. Create a living blueprint of your organization.

What is a process map

A process map is a planning and management tool that visually describes the flow of work. Using process mapping software, process maps show a series of events that produce an end result. It shows who and what is involved in a process and can be used in any business or organization and can reveal areas where a process should be improved.