Solve issues faster with the root cause analysis process

Lucid Content

Reading time: about 4 min

Topics:

If you’ve ever spent a summer pulling weeds out of your backyard, you know that for many weeds, you have to pull out the entire plant including the roots or else they're bound to come back.

Similarly, when a problem occurs within your company, the issue is bound to continue if you don’t identify and eliminate its cause. Figuring out what disrupts production and taking steps to correct the problem is the basis of any root cause analysis. And if you’ve never performed root cause analysis before, you’re in luck—we’ll walk you through the benefits and different methods you can use.

What is root cause analysis?

What is root cause analysis?

Root cause analysis refers to any problem-solving method used to trace an issue back to its origin. You’ll discover what happened, how it happened, why it happened, and what steps are needed to prevent similar issues.

Similar to removing weeds from a garden, a root cause analysis isolates and removes the source of a problem.

Benefits of root cause analysis

Inefficient processes waste time, money, and other resources. Temporary fixes only mask the problem or delay the effects until later. Using a root cause analysis, organizations identify the source of a problem and implement permanent and lasting solutions to prevent future issues.

When to use a root cause analysis

Root cause analysis is especially useful in repeated situations or processes, like assembly lines. However, you can use a root cause analysis in any number of situations, before or after an issue arises, including:

- Everyday accidents

- Medical mistakes

- Manufacturing errors

- Human error

- Risk analysis

Root cause analysis process

Ready to get started? Follow these steps to perform root cause analysis and resolve any problem at your company.

1. Define the problem

Clearly identify problematic events and list out the specific symptoms of the issues. The first step in the root cause analysis process is understanding the problem or problems your organization faces.

2. Collect data

How long have these issues been going on? What are the signs of proof of these problems or issues? What type of impact has the issue caused? Are the impacts measurable, e.g. loss of time, productivity, inventory, etc.?

Go directly to the source to collect the most accurate data. Involve everyone who has been impacted by the issue in the data collection phase to gain as much insight as possible.

3. Identify possible causal factors

Was there a series or sequence of events that led to the problem or allowed the problem to occur? Are there additional problems that stem from this?

4. Pinpoint root causes

Look over your list of potential causal factors, and determine the real reason this problem or issue occurred in the first place. Dig deep to examine each level of cause and effect and the events that led to the unfavorable outcomes.

5. Implement solutions

Ask yourself what you can do to prevent the issue from occurring again. What solutions are necessary? Who will be responsible for the solution and its implementation? Are there any risks associated with implementing the chosen solution?

Rely on the information you gathered through your cause-and-effect diagram to identify what changes need to be made. Use an impact analysis to understand the positive and negative consequences of your solution.

Root cause analysis can be used to assess potential future risk or an incident that has already occurred. Lucidchart can help you dissect and identify symptoms of a problem, actual root causes, and possible solutions.

Root cause analysis templates

Now that you know the steps of the root cause analysis process, these templates can help you get started with your analysis quickly!

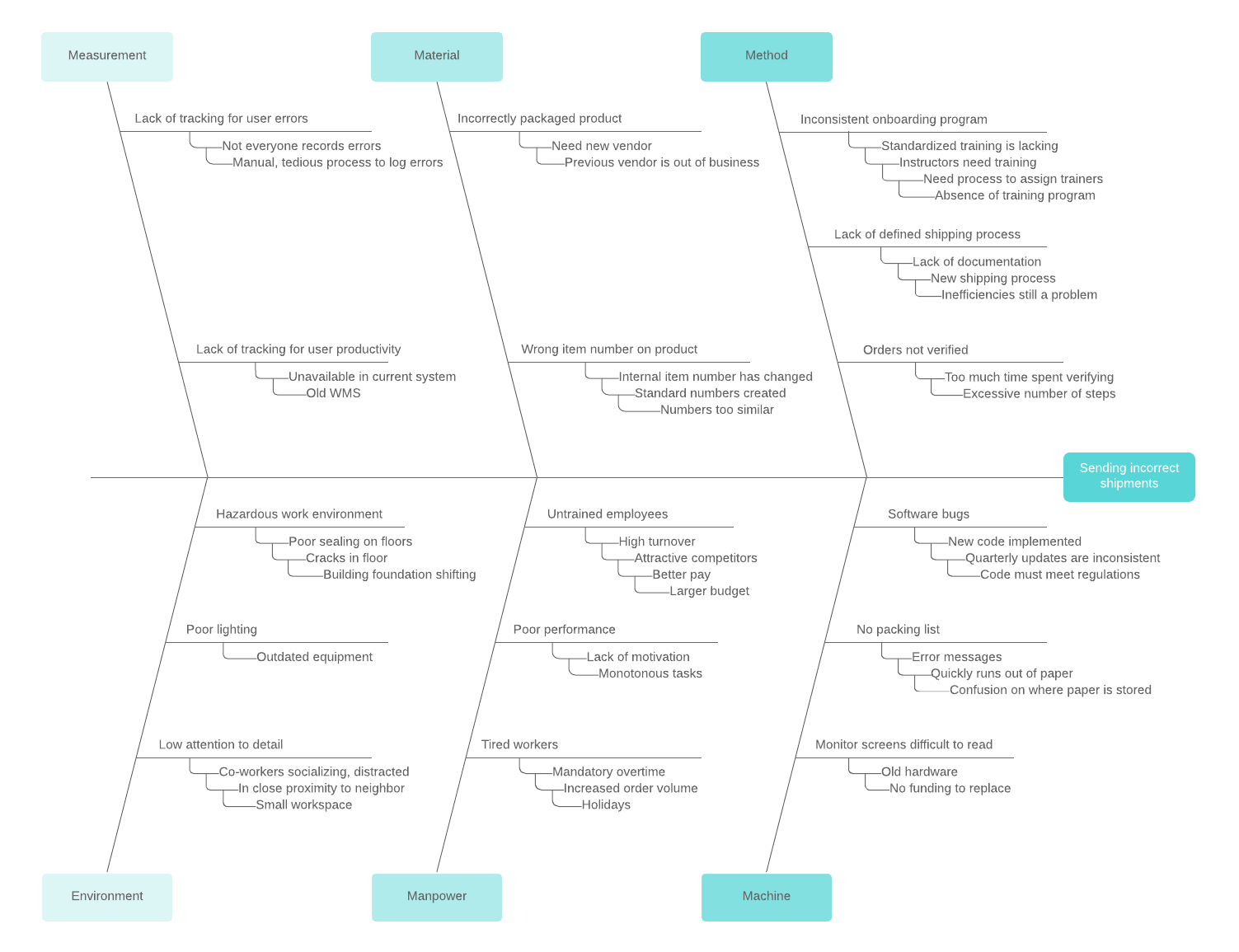

Cause-and-effect diagram

Also known as a fishbone diagram, a cause-and-effect diagram helps you examine potential causes by category. For example, manufacturing industries label the diagram branches with the six Ms (machines, methods, materials, measurements, Mother Nature, manpower) and think of causal factors within each category. These diagrams encourage you to explore all possible causes of a problem instead of stopping at the most obvious conclusion.

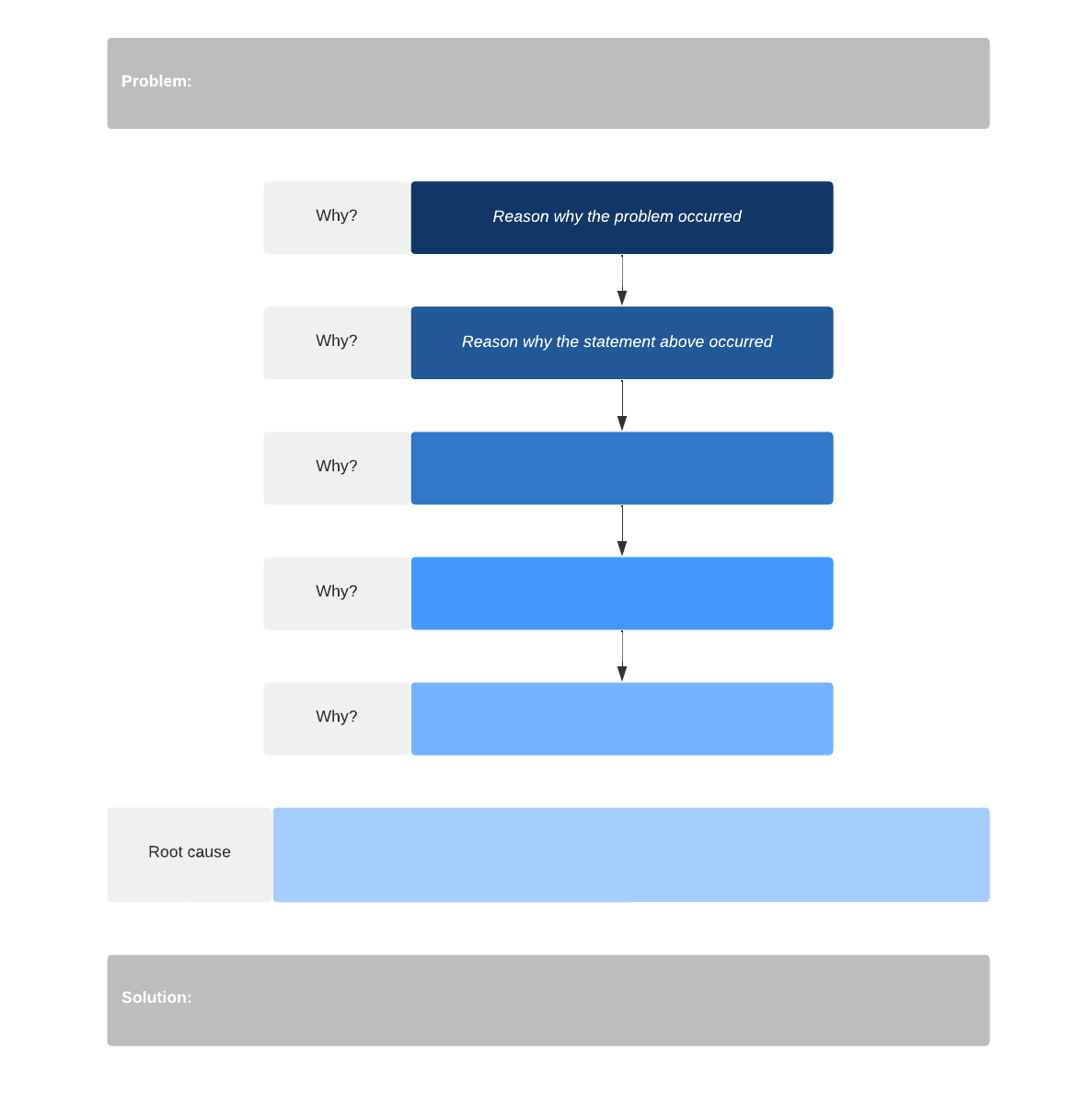

5 whys root cause analysis

The 5 whys method encourages you to keep going deeper as you examine an issue. Ask “Why?” at least five times until you’ve reached the catalyst. Check out our 5 whys template to begin your own analysis.

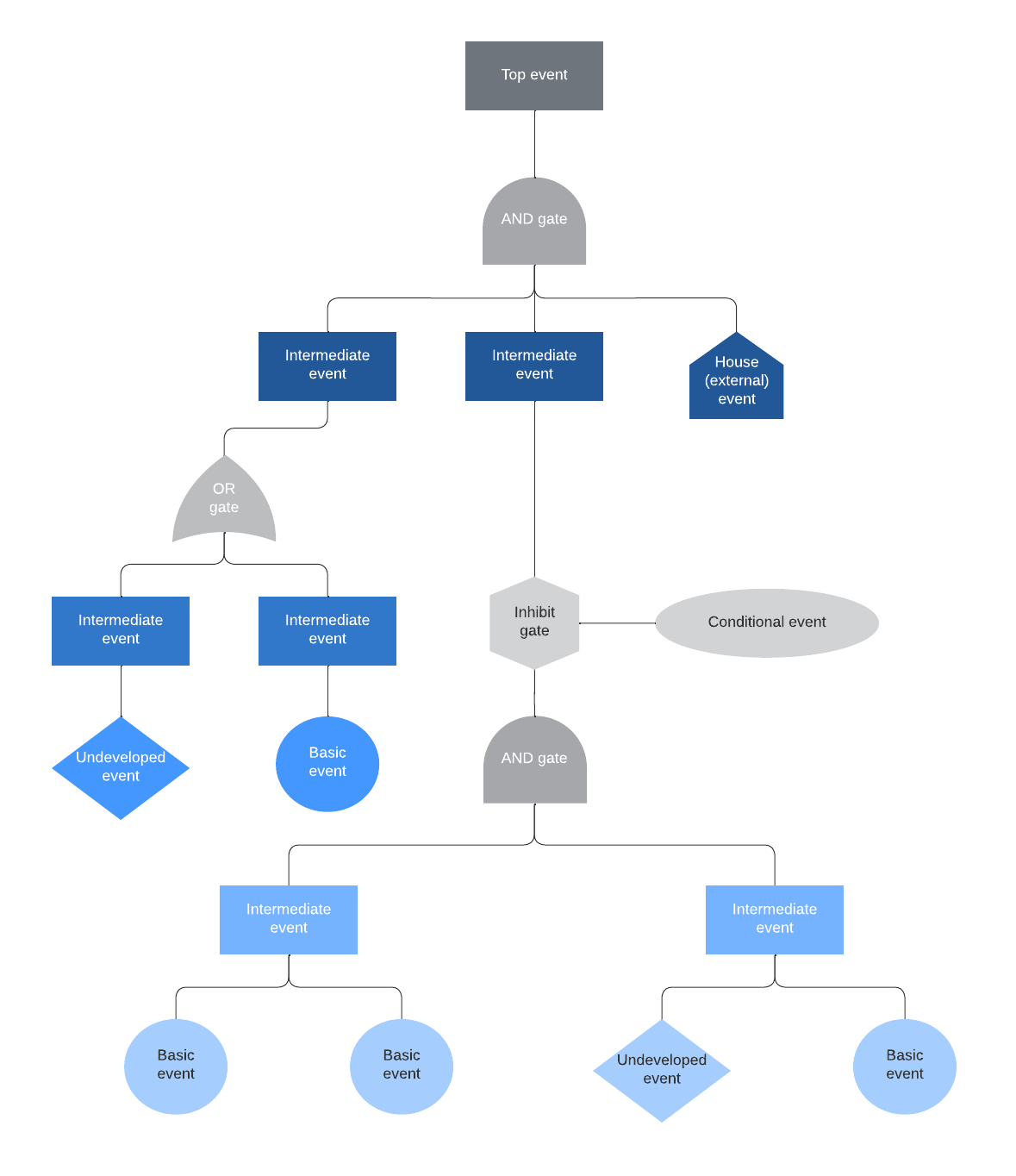

Fault tree analysis diagram

A fault tree analysis diagram can help you visualize the possible causes of a system failure to examine the reliability of your systems and ultimately, improve your systems.

Root cause analysis can be used to assess potential future risks or an incident that has already occurred. Lucidchart templates can help you dissect and identify symptoms of a problem, actual root causes, and possible solutions.

Get started conducting your own root cause analysis with this cause-and-effect diagram template.

Try templateAbout Lucidchart

Lucidchart, a cloud-based intelligent diagramming application, is a core component of Lucid Software's Visual Collaboration Suite. This intuitive, cloud-based solution empowers teams to collaborate in real-time to build flowcharts, mockups, UML diagrams, customer journey maps, and more. Lucidchart propels teams forward to build the future faster. Lucid is proud to serve top businesses around the world, including customers such as Google, GE, and NBC Universal, and 99% of the Fortune 500. Lucid partners with industry leaders, including Google, Atlassian, and Microsoft. Since its founding, Lucid has received numerous awards for its products, business, and workplace culture. For more information, visit lucidchart.com.

Related articles

What is gap analysis? 4 steps and examples to use

A strong gap analysis process allows professionals to determine where their businesses are—and where they want it to be. To perform a gap analysis, follow these four simple steps.

What is decision tree analysis?

In this blog post, we will explain how a decision tree analysis works as well as templates to get started.

How to spot and fix inefficient processes

In this article we discuss some things that can cause process inefficiency, how to identify them, and how to minimize or fix them.

How to conduct a 5 whys analysis

Stumped on a business problem? Try using the 5 Whys. By urging you to look deeper into the issue, the 5 Whys analysis can help you discover the root cause of a problem and put you on track to fix it.