It’s an exciting time to be alive. We have answers to conceivably any question, and they all can be accessed in a matter of seconds from a device no larger than our hand.

And yet, despite endless resources, even the best plans go awry—problems still exist that baffle even the strongest of teams. When an unexpected challenge arises, it’s difficult to locate the root of the problem.

Luckily, there’s a solid technique for locating the origin of any difficulty, and it’s called the 5 whys. The 5 whys analysis is a proven technique used by some of the world’s largest companies, and all it requires is a bit of thought (and potentially a Lucidchart template).

The beginning of the 5 whys

The five whys analysis was developed by Taiichi Ohno, the pioneer of the Toyota Production System in the 1950s. He details his method of problem solving in his book, Toyota Production System: Beyond Large-Scale Production. The technique Ohno developed was so effective that Toyota uses it to this day. Ohno saw a problem not as a negative but as an opportunity in disguise.

When approaching a problem in this manner, it becomes an investigative journey and not a barrier. It’s a way to find hope in circumstances that seem dire or overwhelming. Here’s an example of a time Ohno used the five whys to discover the reason for a robot stopping on the assembly room floor:

- "Why did the robot stop?" The circuit has overloaded, causing a fuse to blow.

- "Why is the circuit overloaded?" There was insufficient lubrication on the bearings, so they locked up.

- "Why was there insufficient lubrication on the bearings?" The oil pump on the robot does not circulate sufficient oil.

- "Why does the pump not circulate sufficient oil?" The pump intake is clogged with metal shavings.

- "Why is the intake clogged with metal shavings?" Because there is no filter on the pump.

As you can see in this example, the five whys helped Ohno reach the root cause of the issue: The team needed to add a filter to the oil pump on the robot. You can use the same process to reach the root cause and implement lasting change.

When to use the 5 whys

The five whys can be used for most problems, but it’s most effective for simple to semi-difficult problems. If you’re attempting to solve for complicated difficulties, you’ll find that the root causes split into separate tracks of inquiry that have their own root causes.

In other words, don’t try to solve the reasons for global poverty by asking five questions—it’s much too complex an issue.

Instead, whittle larger problems into smaller ones and solve the root causes of those problems. Use the five whys for manufacturing problems, product release problems, team issues, or organizational problems.

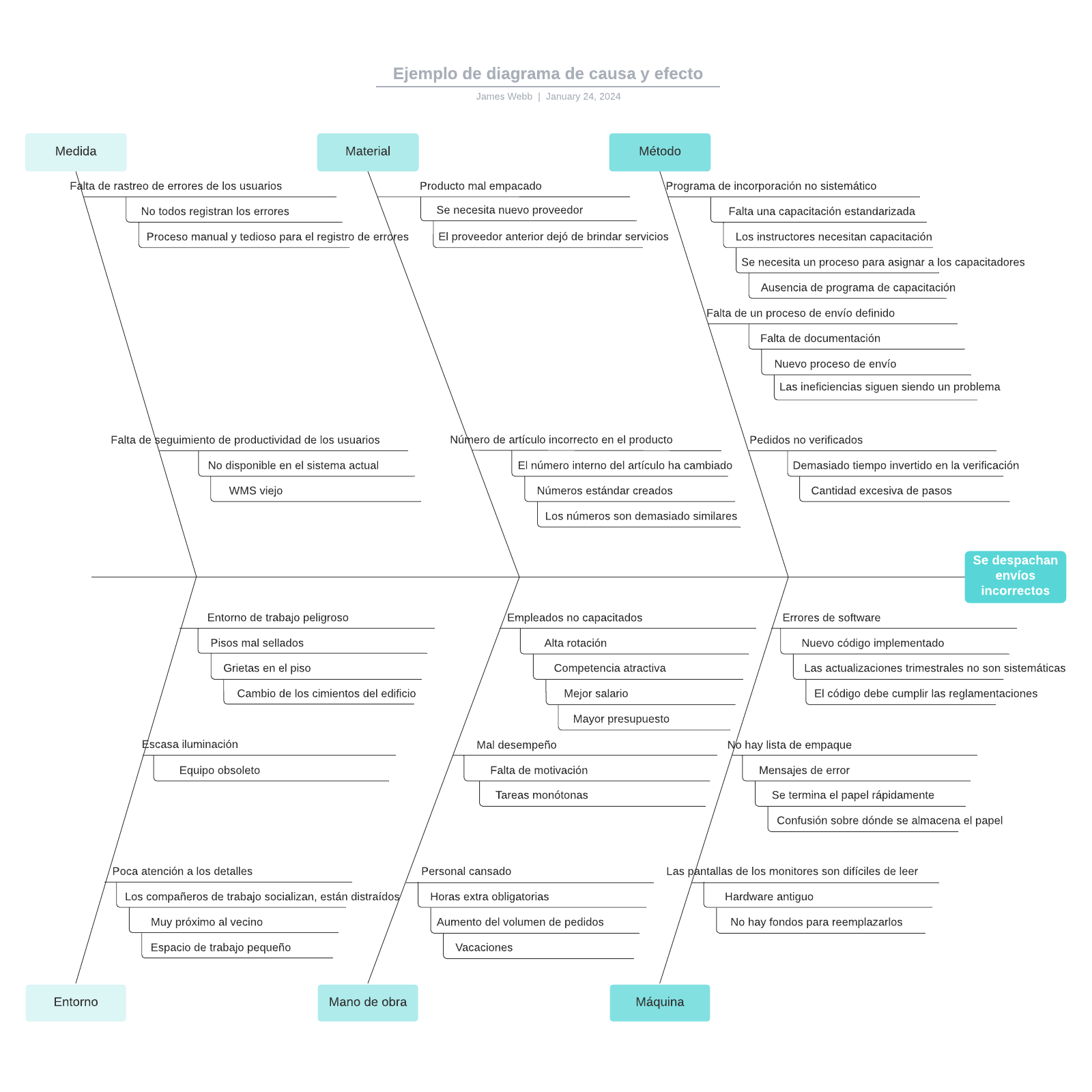

If you’re unsure of whether the five whys is appropriate for the type of difficulty you’re experiencing, it’s not unwise to try it. If the root causes for each “why” split into their own tracks of inquiry, you may be looking at a problem that is more difficult and, therefore, not well-suited to this kind of analysis. In this case, it might be worth switching to a cause-and-effect analysis.

What are the 5 whys?

Every journey comprises steps—at its core, the five why analysis involves asking “Why?” five times, but we recommend adding two additional steps, covered in the next section. This process will enable you to discover the root cause of a problem.

Use Lucidchart to visualize the five whys and keep track of the root causes throughout the investigative process. Our five why diagram can be used again and again to solve whatever small- to medium-sized problems you may experience.

How to use the 5 whys

Though the core of five whys problem solving is only asking five questions, we recommend a few additional steps to bring the brainpower of your team members together and take action on the root causes you find. Use the following method for your five why approach:

1. Gather your team

It’s true that the five whys can be used to solve everyday problems, but you’ll most likely use the five whys in a business setting, so assemble together everyone who is immediately affected by the problem. We’re not talking about an all-hands meeting: Just include those who care most about the solution and can help brainstorm.

2. Define the issue

This step may be easier said than done: sometimes, it’s hard to narrow down exactly what the main problem is. Once you’ve determined the problem, write it down in a one-sentence statement that your team agrees on. Put this sentence in the white bubble at the top of the five whys Lucidchart template.

3. Ask “Why?”

This is where it gets tricky. With your team’s help, ask what’s causing the main problem. These questions need to address concrete problems, not just theories. If you use the Lucidchart template, write this first question in the left-most blue circle.

4. Ask “Why?” four more times

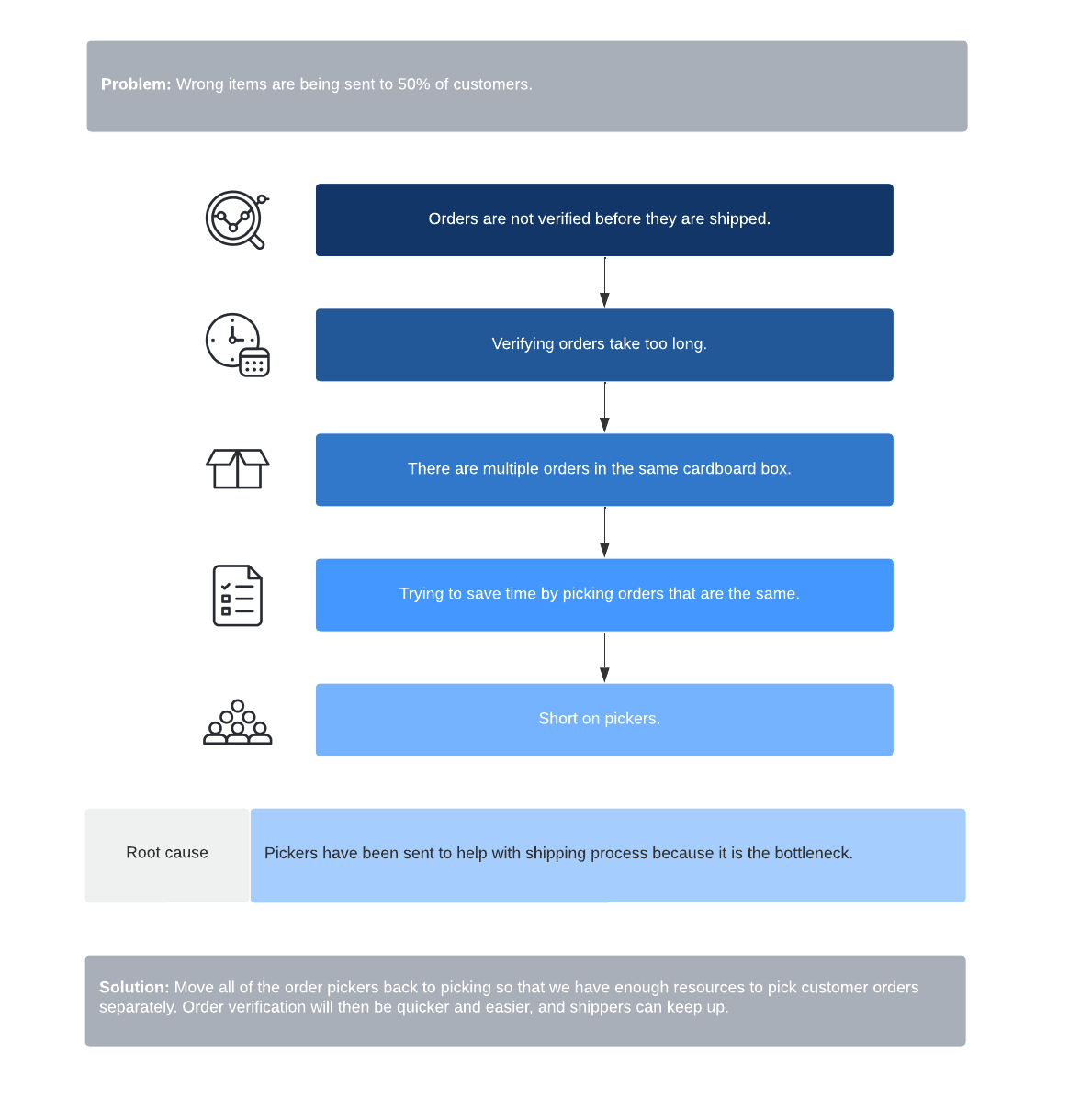

Following the template above in the single lane on the left, ask “why” for each answer. Here’s an example of what that could look like:

Problem: The website wasn’t launched in time.

1. Why?

Answer 1: The developers didn’t have the content they needed.

2. Why?

Answer 2: The copywriter didn’t provide the content.

3. Why?

Answer 3: The copywriter was waiting on approval from the VP of marketing.

4. Why?

Answer 4: The VP of marketing forgot to approve the content.

5. Why?

Answer 5: He was on a business trip.

Solution: A possible solution could be authorizing someone else to approve the content or directing the VP of marketing to set aside time for content approval.

5. Stop at a good solution

In some instances, your team may need to keep asking more “whys.” Sometimes you may need to split into more root causes. But knowing when to stop is a valuable part of the process; otherwise, you’ll find yourself lost and without fixable root causes.

6. Fix the root cause of the problem

Once you know what the root cause of the problem is, you can implement solutions to it. Discuss the best solutions with your team and decide how to proceed.

7. See how it works!

After you’ve implemented your solutions to the root causes, see how it works. Sometimes it’s perfect, and you’ve solved a major problem. Other times, you may need to tweak your “why” questions and their answers. In those instances, just rework the whys, find the root causes, and identify more solutions. The solutions should be targeted and measured and should directly impact the root causes of the whys.

The beauty of the five why process isn’t that it’s perfect: It’s that it gives you a method to rationally find solutions to baffling problems. It’s a way to find calm in a storm of issues. And, frankly, if it worked for Toyota and for a host of other massive companies, it could be the right path for your team.

Learn more about how Lucidchart can help you identify and improve your processes.

Read moreAbout Lucidchart

Lucidchart, a cloud-based intelligent diagramming application, is a core component of Lucid Software's Visual Collaboration Suite. This intuitive, cloud-based solution empowers teams to collaborate in real-time to build flowcharts, mockups, UML diagrams, customer journey maps, and more. Lucidchart propels teams forward to build the future faster. Lucid is proud to serve top businesses around the world, including customers such as Google, GE, and NBC Universal, and 99% of the Fortune 500. Lucid partners with industry leaders, including Google, Atlassian, and Microsoft. Since its founding, Lucid has received numerous awards for its products, business, and workplace culture. For more information, visit lucidchart.com.

Related articles

What is gap analysis? 4 steps and examples to use

A strong gap analysis process allows professionals to determine where their businesses are—and where they want it to be. To perform a gap analysis, follow these four simple steps.

7 steps of the decision-making process

Prevent hasty decision-making and make more educated decisions when you put a formal decision-making process in place for your business.

Bring your bright ideas to life.

By registering, you agree to our Terms of Service and you acknowledge that you have read and understand our Privacy Policy.